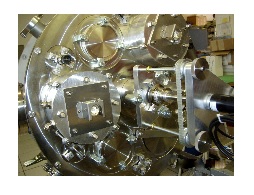

Sputtering Systems According to Customer Requirements

AURION offers sputtering systems in a wide variety of configurations that are specially tailored to customer requirements.

Anfrage an Anbieter senden

Sputtering Systems According to Customer Requirements

1. Introduction

Sputtering is a widely used thin-film deposition technique in industries such as semiconductors, optics, coatings, and nanotechnology. Custom-designed sputtering systems allow for precise adaptation to specific customer requirements, ensuring optimal performance for research, development, and production. 🔹 Key Applications:✔ Semiconductor industry (microchips, MEMS)

✔ Optical coatings (anti-reflective, UV filters)

✔ Hard coatings (wear-resistant layers, DLC coatings)

✔ Solar cell production

✔ Thin-film batteries

✔ Biomedical coatings

2. Customization Options in Sputtering Systems

Customization Feature Description Benefit Number of Targets Single or multi-target configurations Enables multi-layer coatings and alloy deposition Deposition Chamber Size Compact lab-scale to large industrial systems Adaptable to research and mass production Magnetron Type DC, RF, HiPIMS, or pulsed DC magnetrons Optimized for specific material types Substrate Handling Rotating, heating, biasing, or planetary systems Ensures uniform coatings Vacuum System Turbomolecular, cryogenic, or diffusion pumps Achieves required base pressure for high-purity coatings Gas Control System Precise flow of Argon, Oxygen, Nitrogen Controlled reactive sputtering Process Automation Fully automated or manual control Increased reproducibility and ease of use Coating Uniformity Control Moving masks or plasma shaping Enhanced deposition precision3. Advanced Features for High-Performance Sputtering

✅ Reactive Sputtering – Deposition of oxides, nitrides, and carbides✅ Co-Sputtering – Simultaneous deposition of multiple materials for custom alloys

✅ High-Power Impulse Magnetron Sputtering (HiPIMS) – Dense, high-quality coatings

✅ Biasing and Heating of Substrates – Control over adhesion, stress, and crystallinity

✅ In-Situ Monitoring (RGA, Optical Emission Spectroscopy) – Real-time process control

4. Benefits of Customized Sputtering Systems

✔ Tailored Solutions – Optimized for specific material and application requirements✔ Scalability – Systems designed for R&D or industrial production

✔ Improved Coating Quality – High uniformity, adhesion, and purity

✔ Energy and Cost Efficiency – Custom automation and process control

5. Conclusion

Custom-designed sputtering systems provide a flexible, high-performance solution for thin-film deposition across various industries. By optimizing magnetron configuration, chamber design, substrate handling, and process automation, these systems ensure maximum efficiency and precision for advanced material applications.Coating

Surface Treatment

Activation of Plastic Surfaces

High degree of degreasing

Activate and clean surfaces