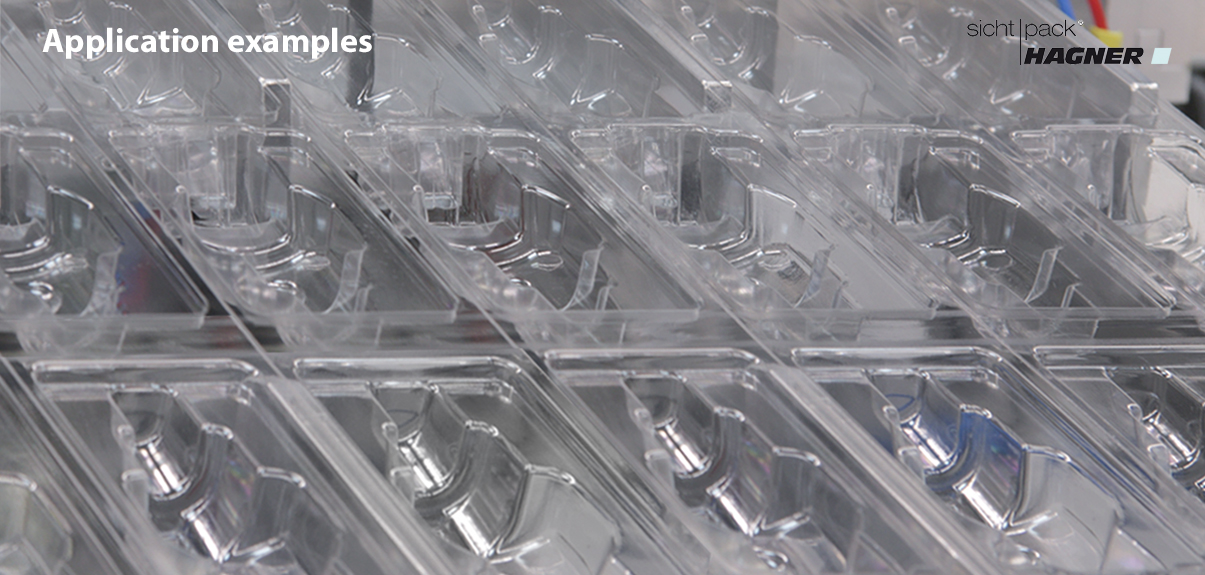

3-layer co-extrusion for clamshells

72280-D Dornstetten

21-23 Musbacher Straße

+49 7443 250

+49 7443 253122

3-layer co-extrusion for clamshells

Anfrage an Anbieter senden

- Outer Layer: The outer layer is usually made of a rigid and durable material that provides structural integrity and protection to the packaged product. Common materials for the outer layer include high-impact polystyrene (HIPS), polyethylene terephthalate (PET), or polycarbonate (PC). This layer contributes to the overall strength and aesthetics of the clamshell.

- Middle Layer: The middle layer is often a softer and more flexible material, which helps improve the clamshell's ability to withstand impact and provide cushioning to the product. Materials used for the middle layer can include low-density polyethylene (LDPE) or polypropylene (PP). This layer enhances the clamshell's resistance to cracking or breaking while also providing some level of flexibility for easy opening and closing.

- Inner Layer: The inner layer is designed to provide a smooth and protective surface for the product. It may include materials like polyvinyl chloride (PVC), polyethylene (PE), or ethylene vinyl acetate (EVA). The inner layer can also be customized to offer specific properties such as anti-static properties or food-grade compliance.

- Enhanced product protection: The multi-layer structure provides impact resistance, protecting the enclosed product from damage during transit or handling.

- Customization: The choice of materials and their specific properties can be tailored to meet the requirements of different products. This includes considerations such as clarity, barrier properties, or chemical resistance.

- Visual appeal: The outer layer can be designed to provide a visually appealing surface, enabling branding, product visibility, and marketing opportunities.

- Convenience and usability: The middle layer's flexibility and the design of the clamshell allow for easy opening and closing, ensuring convenience for end-users.

- Sustainability: Co-extrusion allows for the use of recycled materials in one or more layers, contributing to the sustainability goals of the packaging industry.

1,34 g/cm3

3-layer co-extrusion

180 up to 500 μ* (tolerance +/- 5%)