Plastic parts CNC turning

PROTEC GMBH Zerspanungstechnik

77716-D Haslach im Kinzigtal

12 Schleifmattstr.

+49 7832 7090

+49 7832 70950

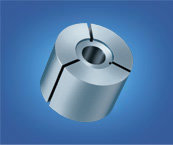

Plastic parts CNC turning

Anfrage an Anbieter senden

-

Material Selection:

- Choose the right plastic material for your application. Plastics vary in terms of properties such as hardness, machinability, and thermal stability. Common plastics for turning include ABS, PVC, POM (acetal), and various types of nylon.

-

Tool Selection:

- Select appropriate cutting tools for machining plastic. Carbide or high-speed steel (HSS) tools are often used. The choice of tool geometry, coatings, and cutting speeds depends on the specific plastic material being machined.

-

Cutting Speeds and Feeds:

- Adjust cutting speeds and feeds based on the properties of the plastic. Unlike metals, plastics often require lower cutting speeds to prevent overheating and melting. Experiment with different settings to find the optimal balance between speed and quality.

-

Coolant and Lubrication:

- While plastic machining generally generates less heat than metal machining, using a coolant or lubricant can still be beneficial. Coolants help to dissipate heat, reduce friction, and improve surface finish.

-

Workholding:

- Use appropriate workholding methods to secure the plastic workpiece. Soft jaws or custom fixtures may be needed to prevent distortion or damage to the plastic part during machining.

-

Tool Path Optimization:

- Optimize the tool paths to minimize tool changes, reduce cycle times, and achieve a smooth surface finish. Efficient programming can also help in minimizing tool wear.

-

Surface Finish Considerations:

- Pay attention to the desired surface finish of the plastic part. Adjust cutting parameters and tool selection to achieve the required surface quality. Post-machining processes like polishing may be required for specific applications.

-

Chip Control:

- Proper chip control is essential to prevent chip buildup and ensure a clean machining process. Adequate chip evacuation prevents re-cutting of chips, which can negatively impact surface finish.

-

CNC Programming:

- Develop CNC programs with precision and accuracy. Consider factors such as toolpath optimization, tool changes, and tool offsets. Thoroughly simulate and test the program before running it on the CNC machine.

-

Quality Control:

- Implement quality control measures to inspect critical dimensions and tolerances. Regularly check the machined parts to ensure they meet specifications.

-

Safety Precautions:

- Follow safety guidelines when operating CNC turning machines. Wear appropriate personal protective equipment (PPE) and be aware of the specific safety considerations associated with machining plastics.

Turning

Gridding

Milling